Master Planning for Process Industries in India

Master Planning and Layout Development are fundamental to the success of large-scale industrial projects, including refineries, petrochemical complexes, and specialty chemical plants. A well-thought-out master plan ensures optimal land utilization, efficient resource allocation, and seamless integration of various process units. It is a strategic blueprint that aligns operational, safety, and environmental objectives with project goals.

What is Master Planning and Layout Development?

Master Planning refers to the creation of a high-level roadmap for the physical and functional development of an industrial facility. It integrates process requirements, utility networks, logistics, and regulatory compliance into a cohesive design.

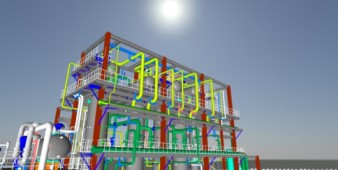

Layout Development, on the other hand, involves detailing the spatial arrangement of equipment, buildings, pipelines, and utilities within the allocated land. Together, these activities provide the foundation for smooth project execution and long-term operational efficiency.

Objectives of Master Planning and Layout Development

- Optimal Space Utilization: Maximize land efficiency while leaving room for future expansion.

- Operational Efficiency: Minimize interconnections, reduce transport distances, and streamline workflows.

- Safety and Accessibility: Ensure safe distances between hazardous units, fire access routes, and easy maintenance access.

- Environmental Compliance: Integrate waste management, pollution control, and green initiatives into the design.

- Cost Optimization: Avoid rework and reduce construction and operational costs through thoughtful planning.

Key Considerations for Master Planning

1. Understanding Project Scope

Define the facility’s purpose, capacity, and future scalability.

Identify key process units, utility systems, and auxiliary facilities.

2. Site Analysis

Evaluate land availability, topography, and soil conditions.

Assess climatic factors like wind direction, rainfall, and temperature for optimal layout design.

3. Regulatory and Environmental Requirements

Adhere to zoning laws, safety regulations, and environmental standards.

Plan for waste disposal, effluent treatment, and emissions control systems.

4. Integration with Process Design

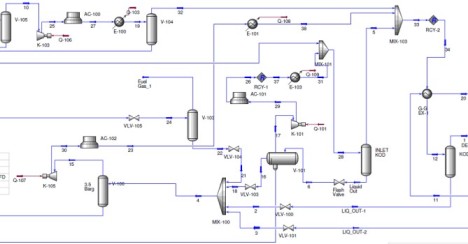

Align layout development with Process Flow Diagrams (PFDs) and Piping and Instrumentation Diagrams (P&IDs).

Optimize equipment placement to minimize piping runs and pressure drops.

5. Utility and Logistics Planning

Map out utility networks for steam, power, cooling water, and process gases.

Plan roadways, rail access, and storage areas for efficient material handling.

Key Deliverables of Master Planning and Layout Development

1. Plot Plans

A high-level representation of the facility, showing the location of key units, buildings, roads, and utilities.

Plot plans consider safety zones, operational flows, and site constraints.

2. Block Diagrams

Simplified schematics showing the spatial arrangement of major process units, utility systems, and infrastructure.

3. Equipment Layouts

Detailed layouts indicating the placement of reactors, columns, heat exchangers, pumps, and other critical equipment.

Includes consideration of maintenance access and future expansion.

4. Utility Corridors

Well-defined corridors for piping, electrical cabling, and instrumentation to ensure easy maintenance and minimize interference.

5. Hazard Zones and Safety Features

Definition of hazardous zones (flammable/explosive areas) and safety measures like firefighting systems, escape routes, and emergency shutdown areas.

Steps in Master Planning and Layout Development

1. Conceptual Planning

Collaborate with stakeholders to understand project objectives, constraints, and future needs.

Create conceptual block layouts for discussion and alignment.

2. Preliminary Layout Design

Develop plot plans and equipment layouts based on process requirements.

Consider space requirements for roads, utilities, and safety features.

3. Safety and Environmental Review

Conduct HAZID studies to identify potential risks in the layout.

Include features like firewater networks, blast walls, and spill containment systems.

4. Detailed Layout Development

Finalize layouts with detailed equipment placement, utility routing, and road designs.

Validate layouts against PFDs, P&IDs, and 3D models for accuracy.

5. Stakeholder Approval

Present finalized plans to project owners, contractors, and regulators for review and approval.

Challenges in Master Planning

1. Land Constraints

Limited land availability may require creative layouts or vertical stacking of equipment.

2. Safety Compliance

Balancing safety requirements with operational efficiency can be complex.

3. Integration with Existing Facilities

Brownfield projects require careful coordination to avoid disruptions to ongoing operations.

4. Dynamic Requirements

Accommodating last-minute changes in process design or project scope can impact the master plan.

Importance of Master Planning

1. Risk Mitigation

Proper planning ensures safe separation of hazardous units, reducing the likelihood of accidents.

2. Cost Control

A well-optimized layout minimizes material wastage and reduces operational costs.

3. Future Scalability

Thoughtful planning leaves room for future expansions without significant rework.

4. Improved Efficiency

Streamlined layouts reduce transport distances, energy losses, and maintenance costs.

Conclusion

Master Planning and Layout Development is not just about arranging equipment and buildings; it’s about envisioning the future of your facility. For refineries, petrochemical plants, and specialty chemical units, a well-executed master plan ensures that every inch of space contributes to operational efficiency, safety, and profitability.

By leveraging expertise in process design, safety studies, and regulatory compliance, a strong master planning phase sets the stage for a successful project lifecycle. With meticulous attention to detail and collaboration between stakeholders, Master Planning becomes the foundation for industrial excellence.