Project Cost Estimation & Tenders Services

In complex industrial projects—like refineries, petrochemical plants, and chemical process facilities—precise estimation and structured tendering are non-negotiable. These processes ensure technical feasibility, financial viability, and contractual clarity right from the early stages. Let’s explore the key activities that shape this critical phase:

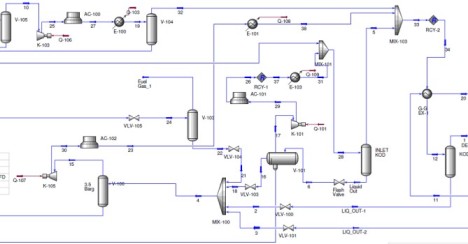

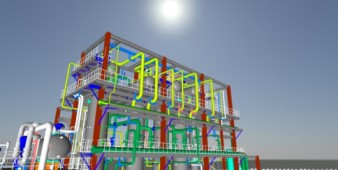

🔍 1. Multi-Disciplinary Preliminary Engineering

Project teams initiate coordination across all disciplines—process, piping, civil, mechanical, electrical, and instrumentation—to define scope, estimate quantities, and outline technical requirements. This cross-functional approach creates a reliable foundation for cost forecasting.

📋 2. Bill of Materials (BoM)

Each engineering discipline develops a detailed list of equipment, bulk materials, and systems. This BoM captures both major and minor items needed during procurement and construction, ensuring no component is overlooked.

💰 3. Schedule of Rates (SOR)

Instead of relying on assumptions, estimators use predefined schedules of rates based on past projects, market intelligence, and government norms. These SORs provide unit pricing for activities like excavation, installation, fabrication, and commissioning.

📦 4. Vendor Offer Collection

To capture real-world pricing and lead times, procurement teams issue RFQs to qualified vendors. They evaluate technical compliance and commercial terms, which adds practical accuracy to the budget.

⚖️ 5. Rate Analysis

Estimators break down unit costs into materials, labour, tools & tackles, and overheads. This process ensures transparency and prevents cost escalation during execution.

📊 6. Cost Analysis & Comparison

The team performs a comparative study of multiple vendor offers and internal estimates. They evaluate hidden costs, exclusions, and delivery schedules to make informed sourcing decisions.

💼 7. Overall Project Costing

Next, estimators consolidate all costs—including engineering, procurement, construction, commissioning, contingency, and project overheads—into a single capital cost summary. This enables realistic budgeting and investment planning.

📑 8. Technical Specifications

Engineering teams draft detailed specifications that define material grades, design codes (like ASME/API), performance criteria, and testing standards. This ensures that all bids are aligned with project needs.

🧾 9. Execution Tender Preparation

Finally, the tender package comes together. It includes the Invitation to Bid (ITB), Scope of Work (SoW), SOR, technical specs, T&Cs, and interface documents. The tender format—item rate, EPC, or LSTK—is chosen based on project complexity.

✅ Why This Matters

When executed thoroughly, estimation and tendering streamline execution, reduce claims and rework, and establish strong contractor alignment. In short, they form the bedrock of project success.

Frequently Asked Questions(FAQ)

1. What is estimation and costing in industrial projects?

Estimation and costing define the expected investment required to design, procure, and construct a facility. It includes quantification of materials, labor, equipment, and indirect costs to assess the total project value and economic feasibility before execution.

2. Why is estimation important during project development?

Accurate estimation ensures budget control, resource planning, and investment decisions. It also forms the foundation for project financing, tender evaluation, and risk management throughout the engineering and construction phases.

3. What is the difference between preliminary, budgetary, and detailed cost estimates?

-

Preliminary Estimate: Rough figure used during concept or feasibility stage (accuracy ±30–40%).

-

Budgetary Estimate: Based on FEED data with improved accuracy (±15–20%).

-

Detailed Estimate: Derived from full BOQ and engineering drawings (±5–10% accuracy), used for tendering and contract award.

4. What is a Bill of Quantities (BOQ)?

The BOQ (Bill of Quantities) lists all measurable quantities of materials, components, and work activities needed for the project. It allows bidders to price uniformly, ensuring transparency and comparability during tender evaluation.

5. What is the Schedule of Rates (SOR)?

The Schedule of Rates (SOR) provides standardized unit rates for construction materials, labor, and services, typically issued by government departments or organizations. It serves as a reference baseline for cost estimation, budgeting, and rate analysis.

6. What are the main components of a detailed project cost estimate?

A comprehensive cost estimate typically includes:

-

Direct costs: Materials, labor, equipment

-

Indirect costs: Supervision, testing, QA/QC

-

Contingencies and escalation

-

Taxes, duties, and freight

-

Contractor overheads and profit margins

7. How are cost estimates developed during FEED and Detailed Engineering?

During FEED, estimates are based on design data, preliminary MTOs, and vendor quotes for major equipment.

During Detailed Engineering, estimates are refined using final BOQs, vendor quotations, fabrication data, and actual construction inputs for higher accuracy.

8. What are the steps involved in tendering and bid evaluation?

The tendering process typically involves:

-

Preparation of tender documents (BOQ, specs, drawings)

-

Floating of tenders (EPC or package-wise)

-

Technical bid evaluation (TBE)

-

Commercial bid comparison (CBE)

-

Negotiation and recommendation for award (RFA)

9. How does technical specification preparation support estimation and tendering?

Technical specifications define design standards, material grades, workmanship quality, and testing criteria. These documents ensure uniform understanding among bidders, eliminate ambiguity, and allow fair price comparison.

10. How does standardization in BOQ and SOR improve project control?

Standardized BOQs and SORs maintain consistency across multiple packages, reduce errors in scope definition, and simplify cost tracking and progress measurement during project execution.

11. How do estimation and costing integrate with procurement?

Accurate estimates help procurement teams prepare budgetary requisitions, bid comparisons, and vendor negotiations, ensuring that final purchase costs align with the approved project budget.

12. What tools or software are commonly used for estimation and tender management?

Typical tools include:

-

MS Excel / CostOS / Candy / Cleopatra Enterprise – Estimation & cost analysis

-

SAP, ERP systems – Procurement & budgeting integration

-

Primavera / MS Project – Schedule-linked cost control

-

Digital tendering portals – Bid management & evaluation

13. How does value engineering relate to estimation and costing?

Value engineering (VE) reviews the design and scope to optimize cost without compromising function or safety. It identifies alternate materials, modular construction options, and efficient methodologies to enhance project economics.

14. What is the role of a cost engineer or estimator in a project?

The cost engineer develops and updates cost models, verifies contractor submissions, manages change orders, and supports project management with real-time cost control and forecasting throughout the lifecycle.

15. How does estimation accuracy improve project execution and control?

A well-prepared cost estimate allows effective monitoring of budget vs. actuals, early identification of cost overruns, and timely corrective actions — ensuring project financial discipline and predictability.

16. How are tender documents structured for industrial projects?

Typical tender documents include:

-

Invitation to bid (ITB)

-

Instructions to bidders

-

General and special conditions of contract

-

Technical specifications and drawings

-

BOQ and SOR

-

Commercial bid format and compliance checklist

17. How do you ensure fairness and transparency in tendering?

By adopting two-bid systems (technical and commercial), conducting open bid evaluations, and maintaining traceable documentation, the tendering process ensures objectivity, competitiveness, and auditability.

18. What are typical challenges in estimation and tendering for industrial projects?

Challenges often include incomplete data, fluctuating material prices, scope ambiguity, and multiple vendor interfaces. Using historical data, verified benchmarks, and robust risk allowances helps overcome these uncertainties.

19. How does estimation contribute to financial closure and project funding?

A validated and auditable estimate supports lenders and investors by providing CAPEX justification, cash flow projections, and project viability analysis, forming the foundation for financial closure.

20. What makes an estimation and tendering consultant reliable?

A credible consultant provides:

-

Proven industrial project experience

-

Cross-disciplinary knowledge (civil, mechanical, E&I)

-

Access to market databases and vendor networks

-

Transparent methodologies and reporting formats

Such expertise ensures accuracy, traceability, and client confidence in cost outcomes.