Packaged Sewage Treatment Plant Manufacturing Solution

TakViksh Modular Packaged Sewage Treatment Plant is based on an indigenously developed patented Hybrid Granular Sequential Batch Reactor (HgSBR) technology.

With the help of this Biological Treatment Technology, within a single reactor we can produce the combined effects of aeration, coagulation, flocculation, floatation, reduction, deposition…

BIOLOGICAL PURIFICATION

Growth of Micro organisms in the form of BIO-BEADS achieves

- achieves high biomass concentrations

- achieves effective nutrient removal

- simplifies biomass-treated wastewater separation

- decreases the pollutant load to below acceptable levels

BIO-BEADS removes organic matter (COD/BOD), reactive nitrogen (ammonium, nitrate, nitrite), phosphorus and other contaminants from wastewater..

Additionally, biological treatment removes colour, turbidity, total suspended solids, and decreases microbial load (faecal coliforms) in the sewage.

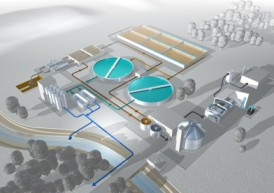

PROCESS CONFIGURATION

- The Hybrid technology of SBR and BIO-BEAD formation use native microbes of waste water for removal of contaminants.

- Single reactor carries various process operations like of filling, mixing, settle and/or decant phases.

- Reactions are partitioned into anaerobic and aerobic phases.

- Length of cycle and individual phases will depend on influent characteristics and treated effluent quality requirements.

- Batch operation can be converted to Continuous Operation based on requirements.

ADVANTAGES

- Fully automated plant

- As small as 1 kLD plant upto large MLD plants

- Modular single reactor tank design consumes very less space

- Optimizes Energy Consumption and non-power intensive process

- No addition of any chemical

- Do not require any secondary clarifiers

- Substantially Removes Suspended Solids and Silica BOD, COD, Colour to international norms

- Destruction and Removal of Bacteria, coliforms, and Cysts (Disinfection)

- Simultaneous Carbon, Nitrogen and Phosphorous removal

- No foul smell from process

- Easy integration into existing process

- Very Low CAPEX & OPEX

- Enables Zero Liquid Discharge

USAGE OF TREATED WATER

- Irrigation and Gardening use

- General washing and Toilet flushing

- General Utility purpose

- Construction Water

- Makeup / Integration to Cooling Water systems

- Integration to fire water

- Feed to Boiler

- Integration to mainstream process system

- Any other usage as desired by end user

APPLICATION OF TakViksh pSTP

- Residential Colonies and Societies

- Remote Camp sites and facilities

- Exhibition Centres

- Construction Sites

- Highly Congested Localities

- Hotels and Restaurants

- Bus station, Railway station, Airports etc

- Tourist places

- Ships & Offshore Platforms

- All kinds of Industrial plants

- Municipality

- Small Towns and Villages