front-end engineering design (feed) service in India

In the world of industrial engineering, especially in sectors like oil & gas, refineries, petrochemicals, and specialty chemicals, Front End Engineering and Design (FEED) plays a critical role in defining the success of a project. FEED ensures that every technical and economic aspect of the project is meticulously planned before entering the detailed design or execution phase.

Let’s explore the key components, benefits, and impact of FEED services in industrial projects.

What is FEED?

FEED (Front End Engineering and Design) is a crucial project development phase focused on defining technical and financial requirements. This stage involves creating the groundwork for project execution by integrating engineering expertise with cost and schedule estimations.

It bridges the gap between the conceptual design (early feasibility studies) and the detailed engineering design, providing clarity to all stakeholders about the project’s scope, risks, and expected outcomes.

Key Elements of FEED Services

1. Process Design and Technology Selection

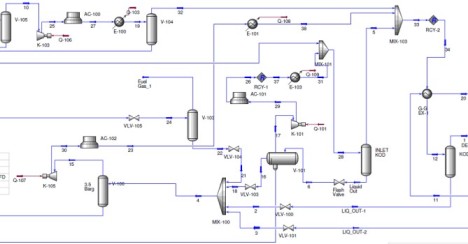

Development of Process Flow Diagrams (PFDs) to outline key processes and production stages.

Creation of Piping and Instrumentation Diagrams (P&IDs) to detail equipment, piping, control loops, and instrumentation.

Selection of process technologies based on operational efficiency, cost, and environmental impact.

Heat and mass balance studies to optimize energy and resource usage.

2. Preliminary Engineering and Specifications

Basic engineering calculations for equipment sizing, layout, and line sizing.

Material of Construction (MOC) selection based on corrosion resistance, pressure, and temperature requirements.

Definition of equipment datasheets and specifications for critical components such as reactors, heat exchangers, and pumps.

3. Cost Estimation and Project Planning

Detailed cost estimation for capital expenditure (CAPEX) and operating expenditure (OPEX).

Development of project schedules with resource allocation and timelines.

Feasibility studies and economic evaluations to assess project profitability.

4. Safety and Risk Assessments

Comprehensive HAZID, HAZOP, and QRA (Quantitative Risk Assessment) studies.

Assessment of environmental compliance and sustainability measures.

Simulation and analysis to mitigate operational risks.

5. Plant Layout

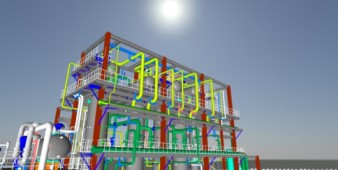

Preliminary layout designs for equipment, piping, and utilities using advanced tools.

Identification of potential space constraints or clashes in equipment placement.

Optimization of layouts for operational ease and safety compliance.

6. Procurement and Vendor Evaluation

Vendor evaluation for long-lead items and critical equipment.

Preparation of bid packages and technical requisitions.

Assistance with technical bid evaluation to ensure compatibility with project requirements.

Why FEED is Essential in Industrial Projects

1. Cost Control and Budget Accuracy

FEED minimizes unexpected cost escalations by providing accurate cost estimates during the early stages of the project. This allows for better financial planning and prevents overruns.

2. Risk Mitigation

With a detailed technical and safety assessment, FEED ensures that potential risks are identified and mitigated before construction begins. This includes addressing process hazards, operational risks, and environmental impacts.

3. Project Alignment

FEED aligns all stakeholders—owners, contractors, and vendors—by clearly defining the project scope and requirements. This reduces ambiguities and ensures seamless communication throughout the project lifecycle.

4. Time Efficiency

By identifying technical challenges early in the design phase, FEED prevents costly delays during execution, saving significant time during the project lifecycle.

5. Regulatory Compliance

FEED ensures that the project complies with all local and international standards, codes, and environmental regulations, minimizing legal risks and ensuring smooth project approvals.

How FEED Services Drive Project Success

A robust FEED phase can save up to 30% of total project costs by preventing scope changes and rework during later stages. It also increases project success rates by clearly defining objectives, risks, and execution strategies.

At TakViksh, we emphasize delivering high-quality FEED services that cater to the unique challenges of industrial projects. Our experienced team integrates engineering excellence with innovative solutions to provide reliable designs that drive project success.

Conclusion

Investing in FEED services is not just a recommendation; it’s a necessity for ensuring the success of any industrial project. Whether you’re planning a refinery expansion, a new petrochemical plant, or a specialty chemical facility, FEED sets the foundation for safe, efficient, and cost-effective project execution.

Are you looking for expert guidance on your next industrial project? Reach out to our team and let us help you with world-class FEED services.

Frequently Asked Questions(FAQ)

1. What is Front End Engineering and Design (FEED)?

FEED (Front End Engineering and Design) is the intermediate phase between Conceptual Design and Detailed Engineering. It develops the technical definition, scope, cost, and schedule basis of a project, enabling clients to make informed investment and execution decisions before moving into EPC or construction.

2. Why is FEED important for industrial and refinery projects?

FEED establishes the technical and commercial foundation of a project. For complex refinery, petrochemical, or process facilities, FEED ensures design optimization, cost accuracy, regulatory compliance, and risk mitigation, resulting in smoother execution and reduced change orders later.

3. What are the key objectives of a FEED study?

FEED aims to:

-

Define process and utility requirements

-

Finalize equipment sizing and preliminary specifications

-

Develop plot plans, PFDs, and P&IDs

-

Prepare cost estimates (+/-10–15% accuracy)

-

Establish execution schedule and contracting strategy

-

Identify risks and define mitigation plans

4. How does FEED differ from Basic and Detailed Engineering?

-

Basic Engineering provides conceptual layouts and design intent.

-

FEED refines those concepts into a well-defined technical and cost package.

-

Detailed Engineering then converts FEED outputs into construction-ready deliverables.

In essence, FEED acts as the bridge between concept and execution.

5. What deliverables are typically produced during a FEED project?

Typical FEED deliverables include:

-

Process Flow Diagrams (PFDs) and P&IDs

-

Equipment lists and data sheets

-

Utility balance and process simulations

-

Preliminary layout and 3D model

-

Project execution plan (PEP)

-

Material take-off (MTO) and cost estimate

-

Schedule and risk register

6. How does a good FEED help in reducing project costs?

A well-executed FEED minimizes design changes, rework, and procurement delays. By locking in design parameters and scope early, it reduces uncertainties and avoids expensive modifications during detailed engineering or construction.

7. What software tools are used in FEED engineering?

Industry leaders use tools such as:

-

Aspen HYSYS, PIPE-FLO, and PRO/II for process simulations

-

AutoCAD, SmartPlant, PDMS, and E3D for layouts

-

Primavera or MS Project for scheduling

-

STAAD.Pro, ETAP, and CAESAR II for preliminary analysis

These ensure data consistency, technical accuracy, and digital continuity to the next project phase.

8. How long does a typical FEED phase take?

The duration depends on project size and complexity. For most industrial plants, FEED typically spans 3 to 9 months, covering process definition, discipline coordination, and cost evaluation to achieve execution-level readiness.

9. How does FEED integrate with HSE and process safety studies?

FEED incorporates early HSE and process safety evaluations, such as:

-

HAZID and preliminary HAZOP

-

SIL assessments

-

Hazardous Area Classification (HAC)

Embedding safety early ensures the design complies with national and international standards and reduces later rework.

10. What are the advantages of engaging the same consultant for FEED and Detailed Engineering?

Continuity between FEED and Detailed Engineering ensures:

-

Consistent design philosophy

-

Efficient data transfer and revision control

-

Reduced learning curve for the team

-

Faster transition to EPC phase

-

Lower engineering rework and improved schedule certainty

11. How accurate is the cost estimate prepared during FEED?

A Class 3 cost estimate (as per AACE classification) is typically prepared during FEED, providing ±10–15% accuracy. This forms the benchmark for project budgeting, financing, and contractor bid evaluation.

12. How does FEED support EPC tendering and contracting?

FEED defines the technical scope, material specifications, and performance criteria, forming the basis for EPC tender documents. This allows apples-to-apples comparison among bidders and ensures transparency in contractor selection.

13. Is FEED mandatory for brownfield or plant expansion projects?

Yes. For brownfield or revamp projects, FEED is critical to assess existing infrastructure, tie-ins, space availability, and operational constraints. It helps develop constructable and safe expansion strategies with minimal plant downtime.

14. How is value engineering integrated into FEED?

During FEED, the team conducts value engineering (VE) workshops to identify cost-effective design options, material alternatives, and modularization opportunities, optimizing CAPEX while maintaining functionality and safety.

15. How to select the right FEED consultant?

A competent FEED consultant should offer:

-

Proven multi-disciplinary engineering expertise

-

Strong process design background

-

Experience in similar industries (refinery, petrochemical, chemical, etc.)

-

Integrated safety and cost engineering approach

-

Digital toolchain compatibility for smooth EPC transition

Such a consultant ensures that the FEED package is technically robust, commercially sound, and execution-ready.